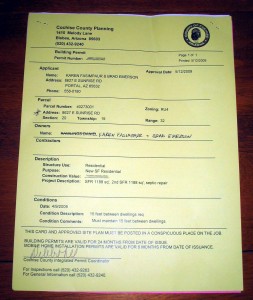

We had a chance to visit two houses built from SIPS (which we’re planning to use for our first house, Tumbeweed) this week. Brad also had another visit with the panel people, and everything continues to look great on that front.

The first house we visited belonged to a prospective customer (at a district that is quite close to us….and for whom I’m now writing a couple grants), where we had dinner. Their house was gorgeous. They built a lot of it themselves. The husband used to do construction and now works in technology, like Brad. Weird, huh? They have a concrete floor, like we’re planning, which was really nice. Their house was a lot like what we want…big open spaces, high ceilings, wood beams. Really great.

The second was a guy who lives in Portal and had one of the first SIPS houses here (built about 8 or 9 years ago). The SIPS people suggested we call him. He was really a great guy. He showed us his whole house, which was unbelievably gorgeous. Again, a big open great room with high ceilings. He was minimal heating and cooling and says it is great. (This is one of the things we’re not sure about.) I wasn’t kidding when I told him that I hoped our house turned out half as nice as his.

After we saw the house, he took us through a photo album of the building process. It was highly instructive. He told us all about different people who helped him and gave us a lot of useful pointers. Like the other people we visited, he designed his house himself. Funny thing is that he said he hired a architect in Bisbee (one of the many we talked to…I think I know of every architect within 500 miles of here), but when he got the final plans, he ended up throwing them out and doing his own. (Another occasion for me to take mental satisfaction in the fact that at least we didn’t pay a ton for our plans.)

He also has a pond on his property. The state paid for part of it because he agreed to restock it with all native species. Pretty cool.

This guy was very encouraging about our building plans. He said that he knew we’d love it here and would end up with a great house. That made me feel good.