It’s been awhile since I last looked at solar power (with difficulty, I’m not calling these solar systems). With the battery house coming along and the house getting electrical, we decided to recheck my energy/solar calculations and place an order. One bright note is that prices have dropped since I last looked.

Part of the learning curve here is learning to think in things like watts and kilowatts and amps (still working on amps). And a difficulty is that people you talk to may think in amps when you’re thinking in watts. Ugh. Not to mention that some people are on the grid which means they have solar panels, but don’t need batteries.

One thing I did was redo the calculation (guess) of our requirements. This is an odd thing to do because your current requirements don’t really apply. They could, but I’m leaving computers on all the time and not all the lights have been switched to CF. Also, the refrigerator here is old… we’ll need to buy new appliances as we sold all ours when we moved. All the new appliances will have the best energy star ratings that make sense; however, they are not here and I cannot measure them. For all I know, in another month or two they will be even more energy efficient.

I did all the calculations from scratch. When I did, I used my handy-dandy Kill A Watt to determine the actual energy we use for certain devices. These were mostly networking and computers. For the rest I used charts and energy star ratings from possible appliances. Anyway, my estimate closely matched my previous estimate of 8 to 9 kilowatt hours a day. (Try figuring how much power you need a week to run the vacuum cleaner, hair dryer, etc.)

Once you get this number, you can plan what you’ll need to support it. The price on solar panels dropped since I last looked; and the watts produced went up. We’re getting a dozen 210 watt panels, which (warning: math to come) means in one hour of sun, you can generate 2520 watts of energy. We get between 6 and 7 hours of sun here from a solar calculation standpoint. So, we are looking at 15120 to 17640 watts of energy generated per day or 15 to 17.5 kilowatts hours. This is best-best case. The panels likely will not produce this much energy and there are other places you lose power. Still, I believe it should easily provide what we need each day plus enough extra to get us through the cloudy days.

Now comes the battery calculation. Standard thinking is that you want enough battery reserve for three days without sun. For us, this means about 27 kilowatts hours of batteries. But, wait… there’s a catch. Depleting a battery below fifty percent is a big no-no. The two things that most determine the life of your batteries are temperature and charge. So you need to double the 27kwh to 54kwh to get your three days.

There’s another important issue with batteries. They say never to add new batteries into a functioning system. The issue has to do with charging the batteries as a group. Let’s say a group of batteries put into a system the same day and never separated are called a flock. They say the individuals in a flock all need about the same amount of charging each day. This means that when you charge the flock, none will be undercharged or overcharged (both are bad for battery life). If you were to add a new battery into a flock it would need less charging than the rest, ergo, either it gets overcharged or all the rest get undercharged.

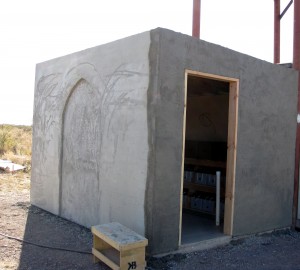

One last thing on batteries is that you can get them sealed or unsealed. Unsealed seems the norm, but there are a couple of issues using unsealed batteries. When they are charging, the batteries give off a dangerous gas (hydrogen gas). It’s explosive for sure and probably not good to inhale. You need to install an exhaust system for when the batteries are charging. This is not too hard (the inverter has a power-out line that comes on when the batteries are charging), but an added expense. Also, I think the room temperature will be more stable without this. The other issue is that water in the batteries has to be maintained. Letting them get low hurts battery life. (Of course it does…) Filling the batteries is an opportunity to spill the battery acid. There are special battery caps to aid in the process, but again an added cost. And, it’s one more thing that needs attention. We decided to go with the sealed batteries and ignore all these issues.

Obviously, you need to be pretty confident about your battery purchase. Solar panels on the other hand, can be added as needed… or one could add wind generators or hydro power (if they lived somewhere else that is). Ho hum. So I gave the battery requirement a bump up somewhere in the 70kwh range.

Plus, you really need a generator. This is too bad, but it seems unavoidable. There will be times when there are four or more days without sun; it’s entirely possible that when it’s not sunny you’ll spend more time indoors, use more electricity, you get the picture. The power center, (inverter, charger, etc.) will also turn a generator on and off as needed to charge the batteries and to provide extra power assuming you need to run the arc welder, while you’re building a time lapse movie, and… running the washing machine. OK, it’s unlikely. Anyway, it’s not a big deal. We’re getting a propane powered generator because we can and it does not need fuel carried to it. I’m getting a smaller generator than I planned on because I don’t think we will need it that much.

There are nifty controls to prevent the generator from coming on while you’re trying to sleep and to run the generator at scheduled intervals for maintenance reasons. (so it can charge its battery, etc.)

All this concern about battery life? Yes, they are the most expensive single item in the system.

The power center we decided on is the Xantex XW System. The main reason for getting it is that Xantrex has a great reputation and everything fits together. We’ve visited a lot of systems around here and most are made from different parts from different companies. They seem complicated and sometimes a little wacky.

If you’re wondering, we’re going with a 48 volt system. I’m not sure this matters much in our case, but the trend in solar equipment is toward higher voltages. As far as I can tell, the biggest reason for larger voltages is that they can travel (over wire) farther with less loss of energy. We aren’t planning on long runs of DC… but we could. The only real downside to a higher voltage (like 48 volts) is that you have to buy batteries in blocks of 48 volts. Which is to say, in our case, (we are using 12 volt batteries) we have to get batteries in multiples of 4. Four batteries at 12 volts equals 48 volts… assuming the four are wired in series, but that’s a whole new can of worms – ask if you really want to know.

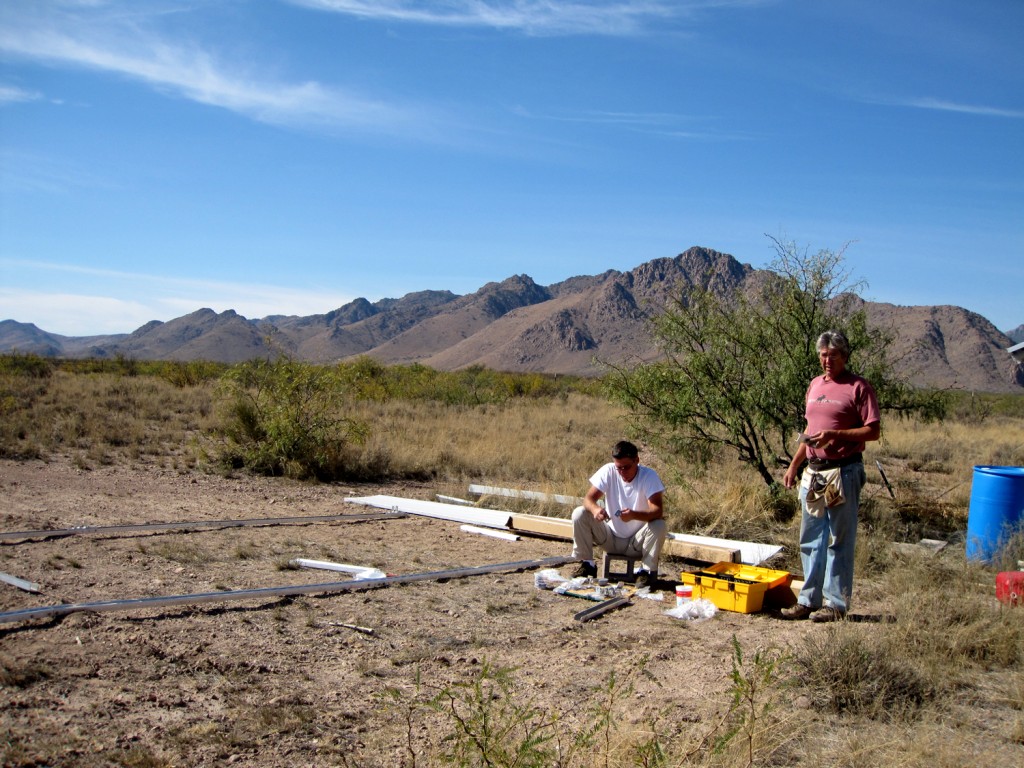

We are getting ground mounts for the solar panels. People keep wanting us to mount these on the roof. If you have lots of land, mounting on the roof isn’t that good an idea. For one, it’s windy up there. (A friend had all his panels blow off his roof — he was lucky most were undamaged.) For two, I don’t want the batteries near the house so I would have to run wire some distance to a battery house – easier to put the panels near the battery house. Also, I can more easily adjust the angle of the panels, when they are on the ground. (The sun here, in the entire northern hemisphere really, is more to the south in the winter and more overhead in the summer.)

This will all get real soon. How close will my estimates be… stay tuned…

brad